Rotary frequency converters, often simply called motor-generator (MG) sets or frequency changers, are electromechanical devices designed to convert electrical power from one frequency to another, or sometimes to stabilize power quality. While modern power electronics have largely superseded them in many applications due to their efficiency and flexibility, rotary frequency converters still hold niche but crucial roles where their inherent characteristics offer distinct advantages.

This article will delve into the characteristics that define these robust machines and explore the diverse application fields where they continue to be indispensable.

The Electromechanical Heart: Understanding Rotary Frequency Converters

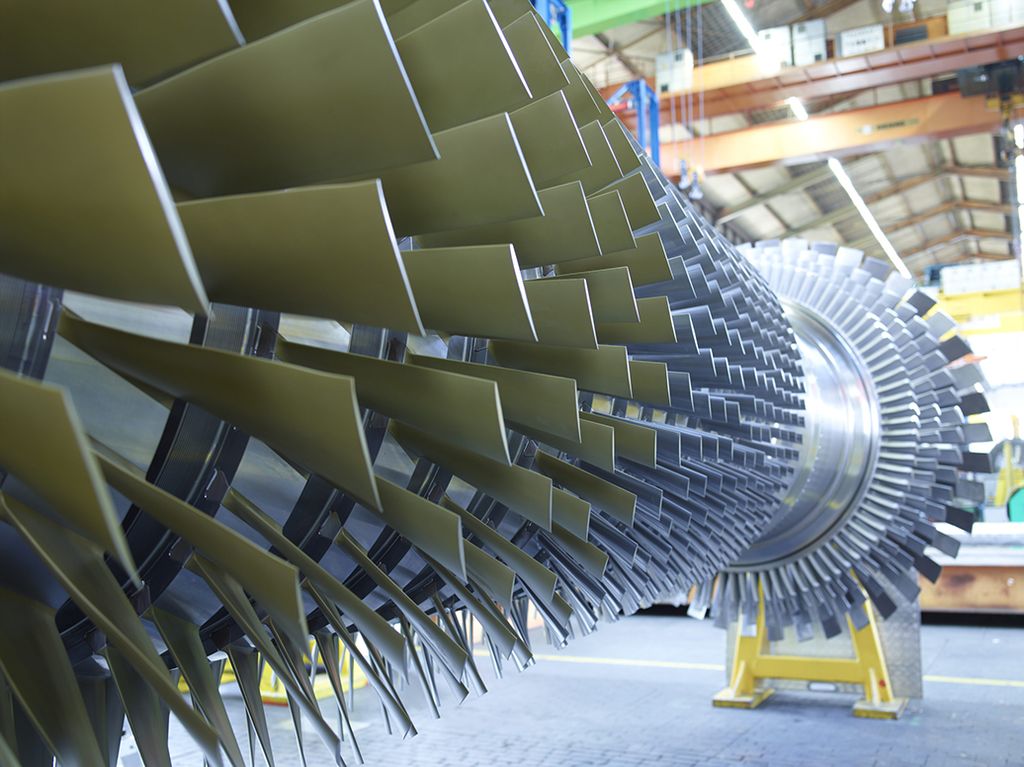

At its core, a rotary frequency converter consists of two main rotating electrical machines: a motor and a generator, mechanically coupled together on a common shaft. The motor drives the generator, and the output characteristics of the generator are different from the input characteristics of the motor.

How They Work:

Imagine a scenario where you have a 50 Hz power supply but need 60 Hz power for specific equipment. A rotary frequency converter would utilize a motor designed to operate on the 50 Hz supply. This motor, in turn, drives a generator specifically wound and designed to produce 60 Hz output. The frequency conversion is achieved by the relationship between the motor’s synchronous speed and the number of poles in the generator, or more simply, by the mechanical coupling allowing the motor to drive the generator at a speed that results in the desired output frequency.

Key Characteristics of Rotary Frequency Converters

Rotary frequency converters possess a unique set of characteristics that distinguish them from their static, solid-state counterparts. These traits often dictate their suitability for particular applications.

- Robustness and Reliability: Being electromechanical machines, rotary converters are inherently robust and can withstand harsh operating conditions, including voltage fluctuations, current surges, and even short circuits, better than many electronic devices. Their design often allows for continuous operation in demanding industrial environments.

- Inherent Short-Circuit Protection: Due to their electromechanical nature, rotary converters exhibit a natural impedance that inherently limits fault currents during a short circuit. This characteristic provides a degree of self-protection for the connected load and the power system.

- Power Factor Correction (Limited): While not their primary function, some rotary converters can be designed with a synchronous motor or generator that can contribute to power factor correction on the input or output side, respectively, by adjusting their excitation.

- Overload Capability: Rotary converters typically possess a significant overload capability for short durations. This means they can supply currents much higher than their rated output for brief periods without damage, which is beneficial for starting motors or handling sudden load demands.

- Frequency Stability (Load Dependent): While they convert frequency, the output frequency of a rotary converter can be slightly affected by changes in load, especially in asynchronous designs. However, synchronous motor-generator sets offer excellent frequency stability.

- Physical Size and Weight: Compared to static converters of similar power ratings, rotary frequency converters are generally larger and heavier due to the presence of rotating machinery and associated mechanical components.

- Noise and Vibration: As rotating machines, they produce audible noise and vibration, which can be a limiting factor in noise-sensitive environments.

- Maintenance Requirements: Being mechanical systems, they require periodic maintenance, including bearing lubrication, brush inspection (for DC exciters or wound-rotor machines), and general mechanical checks.

- Efficiency: Generally, the efficiency of rotary frequency converters is lower than that of modern static converters, particularly at partial loads, due to mechanical losses (friction, windage) and electrical losses in both the motor and generator.

Conclusion

Rotary frequency converters, with their distinct electromechanical characteristics, remain vital components in several specialized industries. Their unparalleled galvanic isolation, inherent robustness, and ability to deliver clean, stable power are invaluable in applications such as aviation, military, and critical testing environments. While modern power electronics offer higher efficiency and greater flexibility in many general-purpose frequency conversion tasks, the unique attributes of the humble motor-generator set ensure its continued relevance in demanding niche applications where reliability, isolation, and resilience are paramount. As industries continue to evolve, the enduring qualities of rotary frequency converters will likely secure their place in the landscape of electrical power conversion for years to come.

More Stories

12 Benefits of Using Yext for Your SEO Strategy

How a Revops Agency Can Eliminate Chaos and Create Revenue Clarity

Why Exhibit Fabrication Is the Key to Memorable Brand Experiences